As a brewer, you want to make sure your customers get the optimum experience when they order your beer in a bar.

Tankbeer systems offer significant benefits for breweries, transporters and bar owners alike. Through a combination of environmental, financial and marketing advantages, tankbeer systems unlock the full potential of beer inside the bar. Despite these benefits, tankbeer is still unfamiliar to many and it is not always clear how the system operates. In this blog we explain the core components of a tankbeer system and how they work together to deliver consistently fresh beer.

Tanks Designed for Perfect Serving Temperature

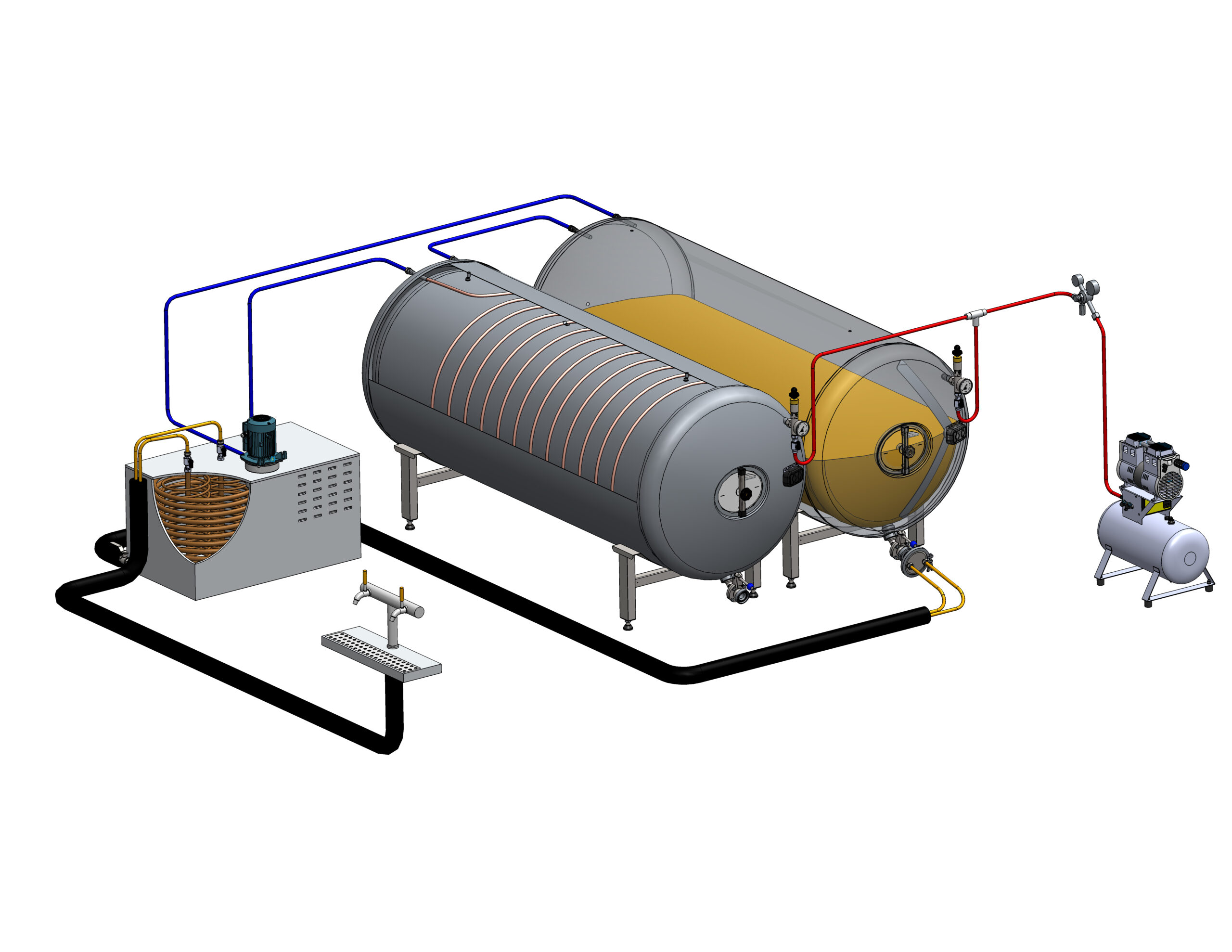

A tankbeer system is built around tanks that are classified as pressure vessels because they operate using air pressure inside the system. The interior of the tank, known as the inner tank, is always made of stainless steel. This material is strong enough to safely withstand internal pressure of up to three bar and fully meets the hygienic standards required for beer storage.

When an inner tank is not insulated, it must be placed inside a cold room to keep the beer at the correct serving temperature. This setup is very common and already provides many of the advantages associated with tankbeer systems.

An alternative solution is to equip the inner tank with copper cooling coils, insulation foam and an outer shell creating a fully insulated and actively cooled tank. With this configuration, the tank no longer needs to be installed in a cold room and can be placed almost anywhere such as a storage cellar or even in the middle of the bar. The outer shell can be finished in various materials including stainless steel allowing it to fit seamlessly into the bar design.

A Closed System for Maximum Freshness

Alongside the tanks, inliners form the core of a tankbeer system. Inliners are specially designed plastic bags placed inside the tanks and filled with beer. They protect the beer from external influences such as air allowing the beer to be dispensed using compressed air instead of carbon dioxide.

The inliner forms stops large amounts of oxygen or gas coming in contact with the beer.This ensures longer freshness, consistent taste and optimal beer quality with every pour.

Supporting Components Behind Every Perfect Pour

A tankbeer system requires additional support equipment to operate safely and efficiently. Compressed air is supplied by an air compressor while a safety valve regulates the pressure inside the tank. This valve ensures that pressure remains at the correct level and guarantees safe operation at all times.

Beer flows into and out of the tank via the piercing unit which connects directly to the inliner. This connection is fully airtight preventing any exposure to air. From the piercing unit a python transports the beer from the tank to the bar taps.

Cooling for both the tanks and the python is provided by standard water coolers. In regions with warmer climates glycol cooling systems can also be used to ensure stable temperatures and consistent serving quality.

Recent articles

Blog: Smart Tank Beer Transport Solutions, Finding the Perfect Setup for you

As a brewer, you want to make sure your customers get the optimum experience when they order your beer in a bar.

Blog: High-Volume Beer Service

As a brewer, you want to make sure your customers get the optimum experience when they order your beer in a bar.

Blog: How a Tank Beer System Works

As a brewer, you want to make sure your customers get the optimum experience when they order your beer in a bar.

Smarter beer transport starts here

As a brewer, you want to make sure your customers get the optimum experience when they order your beer in a bar.

Preview: Duotank at Drinktec 2025

As a brewer, you want to make sure your customers get the optimum experience when they order your beer in a bar.

Blog: Why Beer Tanks Are a Game-Changer for Events

As a brewer, you want to make sure your customers get the optimum experience when they order your beer in a bar.

Combined Tankbeer Transport: Efficiency, Sustainability and Innovation in One

As a brewer, you want to make sure your customers get the optimum experience when they order your beer in a bar.

Blog: comparing single-wall and double-wall beer tanks

As a brewer, you want to make sure your customers get the optimum experience when they order your beer in a bar.

Blog: Why Tankbeer Systems Are the Sustainable Choice for Breweries

As a brewer, you want to make sure your customers get the optimum experience when they order your beer in a bar.