As a brewer, you want to make sure your customers get the optimum experience when they order your beer in a bar.

Tankbeer systems offer great benefits for breweries, transporters, and bar owners. Thanks to environmental, financial, and marketing benefits, tankbeer systems create value and leverage the full potential of beer inside a bar. For many people, tankbeer systems are still unfamiliar, and it is not always clear how the system operates. In this blog, we systematically go through the components of a tankbeer system and how it functions.

Tanks

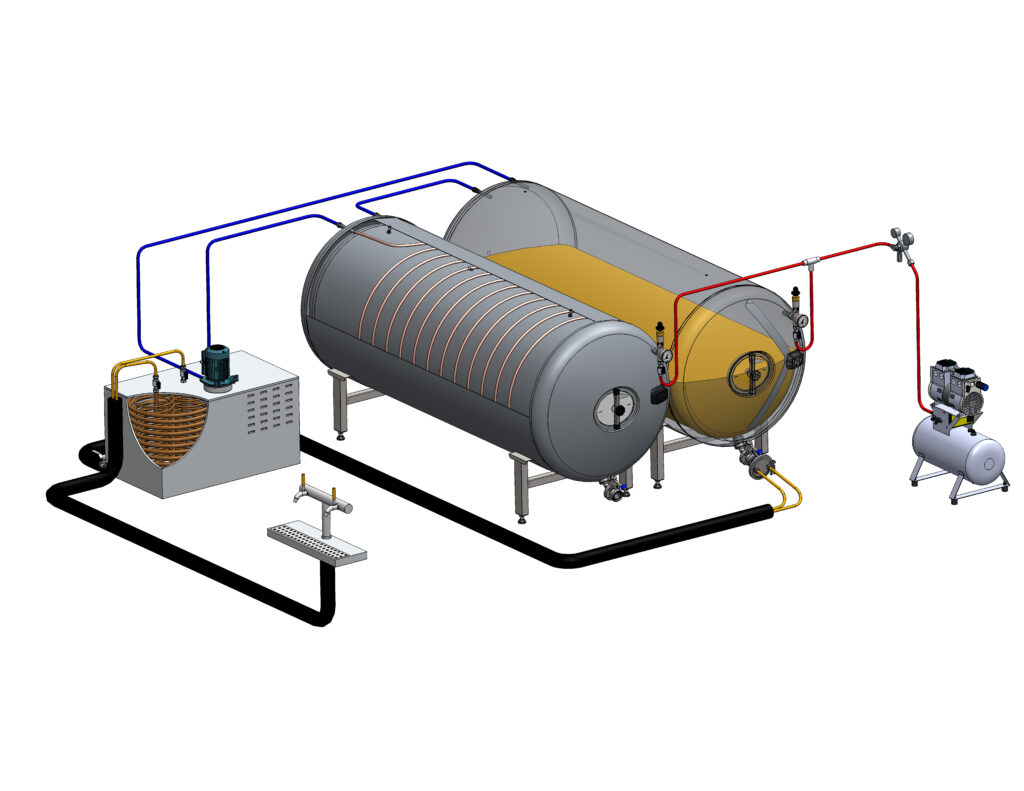

As the name already clearly explains, the system is based around tanks. These tanks are called pressure vessels, as they operate with air pressure on the inside (more about that in the section ‘Inliners’).

This means that the inside of the tank is always made of stainless steel, to be strong enough to handle the pressure of up to 3 Bar. We call the pressure vessel the inside tank.

If an inside tank is left like that, it is non-insulated and needs to be placed in a cold room to keep the beer at the right temperature. This solution is very common and gives many of the benefits of a tankbeer system.

A second possibility is to fit the inside tank with copper cooling coils, insulation foam, and an outside shell. This creates a fully insulated and cooled tank.

By doing so, the tank is no longer required to be used in a cold room; it can be placed almost anywhere, for example in a storage cellar or the middle of the bar. The outer shell can be made from various materials such as stainless steel.

Inliners

Apart from the tanks, the core of a tankbeer system is inliners. These are plastic bags placed inside the tanks. These bags will be filled with beer, keeping it protected from outside influences such as air. This way, the beer can be pushed out of the tank by using air instead of CO².

This offers great benefits, as the beer is not affected by any external factors as soon as it leaves the brewery. All these factors allow the beer to remain fresh for a longer period of time.

Duotank has recently developed the design of their inliners in a new direction, making them more environmentally friendly. From now on, Duotank inliners are produced in such a way that they can be fully recycled after use.

To make this process easier for the end-user, Duotank offers a system for re-collection of used inliners. The recycling process is done by a certified partner, and upon request, the recycling certificate can be shared with the end-user of the inliners.

Support equipment

Of course, other equipment is needed to allow a tankbeer system to operate properly. In terms of pressurized air, the system uses an air compressor. The pressure inside the tank is regulated by a safety valve. This valve ensures the pressure stays at the right level and keeps the tank safe to use.

The beer can flow in and out of the tank via the piercing unit. This is connected via the tank outlet directly into the inliner. Both of these items connect perfectly, creating an airtight connection. To get the beer from the tank to the bar, a python can be connected to the piercing unit. For cooling of the tanks and python, the system works with standard water coolers. In some areas with a warmer climate, a glycol cooler can also be used.

Recent articles

Blog: inner city draught beer delivery

As a brewer, you want to make sure your customers get the optimum experience when they order your beer in a bar.

Duotank Australia: 15 years of unpasteurized tankbeer excellence

As a brewer, you want to make sure your customers get the optimum experience when they order your beer in a bar.

Blog: Factors that influence the freshness of beer

As a brewer, you want to make sure your customers get the optimum experience when they order your beer in a bar.

Winners of the best CSR/Sustainability initiative award

As a brewer, you want to make sure your customers get the optimum experience when they order your beer in a bar.

Case study – Remise 56 Copy Copy

As a brewer, you want to make sure your customers get the optimum experience when they order your beer in a bar.

TANKBEER – Matthias Kopp

As a brewer, you want to make sure your customers get the optimum experience when they order your beer in a bar.

Case study – Remise 56 Copy

As a brewer, you want to make sure your customers get the optimum experience when they order your beer in a bar.