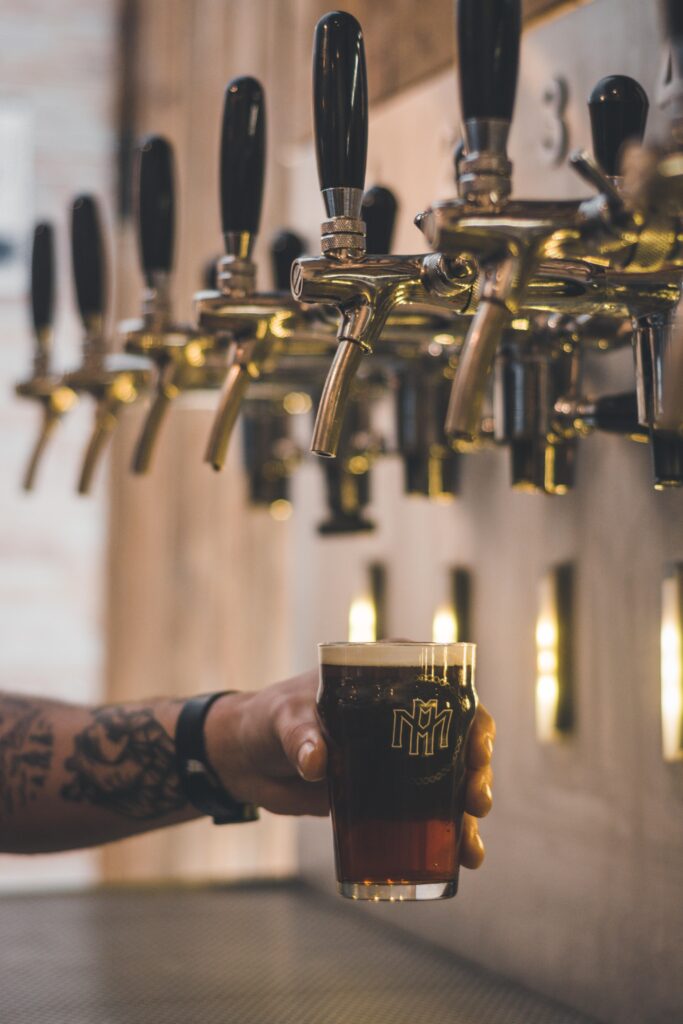

As a brewer, you want to make sure your customers get the optimum experience when they order your beer in a bar.

As a brewer, you want to make sure your customers get the optimum experience when they order your beer in a bar. One of the most important aspects of that experience is, of course, the quality of the beer. After all, beer should be drunk as the brewmaster has intended it: brewery-fresh. But, how do you make sure the quality of the beer does not get affected during transport or storage? In this blog, I explain which factors have the largest influence on the quality of beer and how you can optimize your transport and storage accordingly.

High quality, brewery-fresh beer

More and more breweries are advertising with “brewery-fresh beer”. But what makes beer “brewery-fresh”? And can you serve brewery-fresh beer outside your brewery? Brewery-fresh beer is, of course, beer that is served directly from the lager tank in the brewery. Here the taste of the beer is exactly as the brewmaster has intended it. Or, in other words: it is the best possible quality beer can have.

Ideally, you would want to serve brewery-fresh beer outside of the brewery too. However, to be able to serve it outside of the brewery, you need to preserve the taste of brewery-fresh beer all the way from the brewery to the bar. To make this possible, storage, packaging, transport and dispensing method all need to be chosen carefully.